In-Mold Decorations: Changing Production Requirements

In-Mold Decorations: Changing Production Requirements

Blog Article

Understanding In-Mold Decorations: Techniques, Fads, and Ideal Practices for Ideal Results

In the world of manufacturing, the art of in-mold designs stands as a critical facet of product layout and production. As sectors constantly look for innovative means to enhance aesthetic appeal and performance, mastering the ins and outs of in-mold decors has emerged as a vital ability set. From choosing the appropriate materials to integrating advanced layout trends, the journey in the direction of achieving optimal results in this domain name is complex. By delving into the methods, fads, and best methods that underpin successful in-mold decoration processes, organizations can open a realm of possibilities that not only raise the visual appeal of their items yet also simplify production effectiveness and boost customer involvement.

Product Selection

Material selection is a vital aspect of grasping in-mold decorations, as it straight affects the quality and durability of the last item. When selecting products for in-mold designs, it is essential to take into consideration elements such as compatibility with the molding procedure, the desired visual outcome, and the environmental problems the product will certainly face.

Additionally, the selected material needs to possess excellent adhesion homes to make certain that the decoration sticks strongly to the substrate throughout the molding process. Adhesion in between the product and the decoration is essential for protecting against delamination and ensuring resilient aesthetic allure. Additionally, materials with high warm resistance are chosen for in-mold designs, particularly for items that will be revealed to elevated temperatures during their lifecycle. By very carefully picking the appropriate material for in-mold decorations, suppliers can boost the overall quality and sturdiness of their items, fulfilling the expectations of both clients and end-users.

Style Advancement

A necessary variable in progressing the area of in-mold designs is the continuous exploration and execution of style technology strategies. Style development plays an important role in enhancing the aesthetic appeal, functionality, and overall top quality of items manufactured using in-mold decor processes. By integrating innovative layout aspects, producers can differentiate their items on the market, attract customers, and remain ahead of rivals.

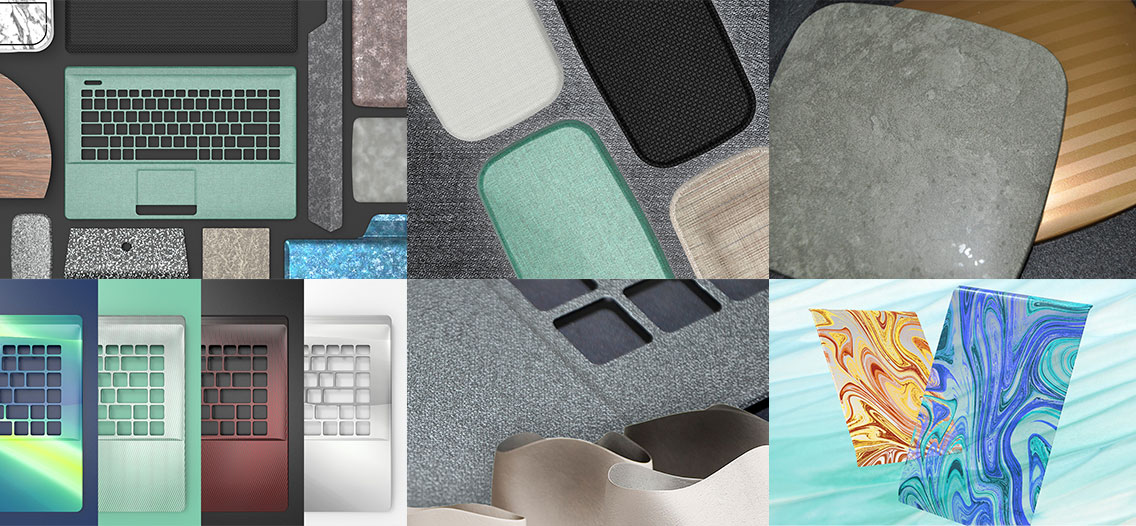

One of the key facets of style development in in-mold decors is the combination of elaborate patterns, appearances, and graphics that were previously challenging to accomplish with traditional design methods. Advanced modern technologies such as 3D printing and digital layout devices make it possible for designers to develop complex and thorough styles that can be flawlessly transferred onto shaped components. Furthermore, the use of vivid shades, metallic finishes, and unique impacts like gloss or matte structures can additionally raise the aesthetic charm of in-mold decorated products.

Furthermore, design advancement expands beyond looks to incorporate functional enhancements such as ergonomic shapes, integrated functions, and personalized elements that deal with certain individual requirements. By accepting layout technology, makers can unlock new opportunities for imagination, customization, and item distinction in the competitive landscape of in-mold designs.

Manufacturing Efficiency

Efficient production procedures are necessary for converting the innovative styles established in the field of in-mold decors into top notch completed products that fulfill market needs and customer expectations. In the realm of in-mold decorations, production effectiveness incorporates various crucial elements that contribute to the general success of the production process.

Additionally, carrying out automation and robotics in the assembly line can significantly enhance effectiveness by streamlining recurring tasks and lowering the margin of error. Automation not just increases try this site the manufacturing process however also improves accuracy and repeatability, causing a more uniform and high-quality output. Taking on lean production principles, such as just-in-time supply administration and waste decrease techniques, can additionally enhance production efficiency by reducing downtime and optimizing source use. In general, a holistic method to manufacturing performance is vital in optimizing the capacity of in-mold design strategies and achieving optimal results in the competitive market landscape.

Quality Assurance Procedures

What are the essential methods for making certain stringent quality control measures in the realm of in-mold decorations? Quality control measures are critical in in-mold design procedures to make certain the production of high-grade and perfect ended up products.

Using advanced technologies such as automated evaluation systems can also enhance the quality assurance procedure by offering trusted and precise information for analysis. These systems can spot blemishes that this post may be missed out on by hand-operated evaluations, consequently improving total item top quality and uniformity.

Regular training and development programs for workers involved in the in-mold decoration procedure can also add to keeping top quality criteria. By educating team on ideal practices, top quality expectations, and the relevance of focus to detail, business can foster a culture of high quality Our site consciousness throughout the company.

Consumer Allure

To improve the marketability of in-mold decor items, comprehending and providing to consumer preferences play a crucial duty in establishing their charm and success. Supplying modification options such as individualized styles, color variations, and textural elements can significantly boost the allure of in-mold decor products.

Conclusion

In-mold decors supply a effective and functional method to boost product visual appeals. By carefully picking materials, accepting ingenious designs, optimizing production processes, implementing quality assurance procedures, and focusing on customer charm, manufacturers can attain optimal results. It is crucial for companies to continually adjust and enhance their methods to remain competitive on the market. In-Mold Decorations. Mastering in-mold designs needs an all natural approach that considers all aspects of the production procedure to guarantee success.

In the realm of production, the art of in-mold decors stands as an essential facet of product design and manufacturing. Style development plays an essential function in enhancing the visual charm, functionality, and total high quality of items produced using in-mold decor processes.One of the essential facets of style development in in-mold decors is the combination of detailed patterns, structures, and graphics that were previously challenging to attain with standard decoration techniques.Reliable production procedures are vital for translating the ingenious designs established in the area of in-mold decorations right into top quality ended up products that meet market demands and customer expectations. Using customization choices such as personalized layouts, color variations, and textural components can considerably boost the allure of in-mold decoration items.

Report this page